Manufacturing, Process, Technology

Harnessing the Power of Automated Workflows in Manufacturing

The manufacturing industry is at a turning point. As global competition intensifies and customer expectations grow, manufacturers face mounting pressure to produce high-quality products faster and more efficiently—all while keeping costs under control. Enter automated workflows: a game-changing solution that addresses these challenges head-on.

By integrating automated workflows into operations, manufacturers can unlock significant improvements in productivity, process accuracy, and scalability. Whether dealing with intricate supply chains, complex compliance requirements, or labor shortages, automated workflows provide the tools to thrive in today’s demanding landscape.

The Benefits of Automated Workflows for Manufacturing

- Streamlined Operations: Automated workflows eliminate manual, repetitive tasks, allowing teams to focus on higher-value activities. For example, digitizing inventory management reduces errors and ensures optimal stock levels without the need for constant oversight.

- Enhanced Quality Control: Consistency is critical in manufacturing. Automated workflows enforce standardized processes, ensuring every product meets stringent quality standards. With real-time monitoring, potential issues can be flagged and addressed before they escalate.

- Improved Collaboration Across Teams: Manufacturing often involves multiple departments, from design and production to logistics. Automated workflows centralize data, providing a single source of truth that keeps teams aligned and projects on track.

- Scalability Without Complexity: Growth can strain traditional processes. Automated workflows simplify scaling by ensuring that systems can handle increased demand without adding unnecessary layers of complexity.

Applications of Automated Workflows in Manufacturing

- Supply Chain Management: Automating tasks like procurement tracking, supplier communications, and delivery scheduling ensures supply chains remain efficient and adaptable, even during disruptions.

- Maintenance and Downtime Prevention: Predictive maintenance workflows monitor equipment health and trigger proactive interventions, reducing downtime and costly repairs.

- Data Management and Optimization: Automated workflows simplify data collection, processing, and analysis, enabling manufacturers to unlock valuable insights, optimize decision-making, and identify trends for continuous improvement. [See our blog post, Best Practices for Data Integrations in Manufacturing]

- Compliance and Reporting: Automated workflows generate accurate reports, track regulatory requirements, and ensure compliance with industry standards, saving time and mitigating risk.

Getting Started with Automation

Implementing automated workflows doesn’t mean a complete overhaul of your systems. A phased approach works best:

- Identify bottlenecks in current processes.

- Evaluate automation tools that integrate seamlessly with existing infrastructure.

- Start small, testing workflows in a controlled environment before scaling.

- Train your workforce to maximize the benefits of new tools.

Why Creed?

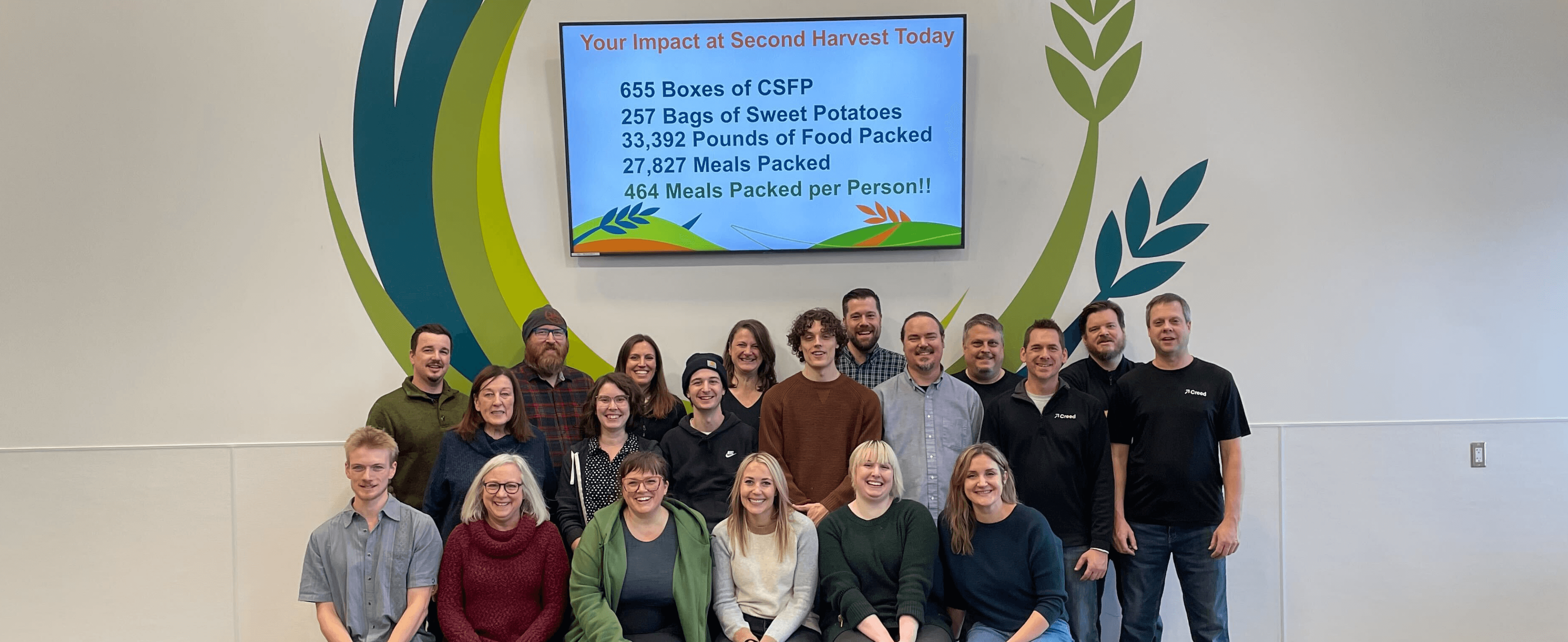

At Creed Interactive, we specialize in creating tailored digital solutions for the manufacturing industry. From custom applications to integrations that support automated workflows, our team designs technology that fits seamlessly into your operations—enhancing efficiency, reducing costs, and positioning you for long-term success.

Let’s explore how automation can transform your manufacturing processes. Ready to revolutionize your manufacturing processes? Let’s build the automated workflows your business needs. Get in touch with us today!